|

● |

The instrument

can provide

products

analysis and

inspection of

quality for oil

solution, fiber

and yarn guiding

factories, or

also for the

R&D.

|

|

● |

Standard

functions: |

|

|

(1) |

Testing the

friction

coefficient of

F/C(fiber and

ceramic yarn

guide), F/M(fiber

and metal strip)

and F/F(fiber

and fiber) |

|

|

(2) |

Analyze friction

coefficient

(both

dynamic/static),

output the

testing files in

average. |

|

|

(3) |

Testing the

fiber tension

during process

and the

unwinding

tension; display

is available for

unwinding

tension

separate. |

|

|

(4) |

Automatic

zero-resetting

and full scale

calibration can

test the

accuracy of

friction

coefficient. |

|

|

(5) |

Analyze

uniformity of

fiber surface. |

|

|

(6) |

Equipped with

yarn guiding

steady device,

which

stabilizing yarn

guiding tension

for friction

analysis |

|

● |

Option

Functions: |

|

|

(1) |

Heating roller

and box can be

simulated

production

condition and

environment,

then improving

the oil solution

and spinning. |

|

|

(2) |

As request,

design kinds

holder of godet

and oil nozzle

to test

whether the

godet and oil

nozzle is

working

normally. It can

control the

production

quality

effective. |

|

|

(3) |

Connecting

R-4021, static

tester, to

analyze the

influence of

difference oil

via fibre

friction and

anti static

volume after

friction. |

|

|

(4) |

Optional oiling

function: the

medium/higher

oil can be oiled

by oil roller;

the lower/lowest

oil can oiled by

ultrasonic,

analyzing

concentration of

oil (process

oil). |

|

● |

Software

Features: |

|

|

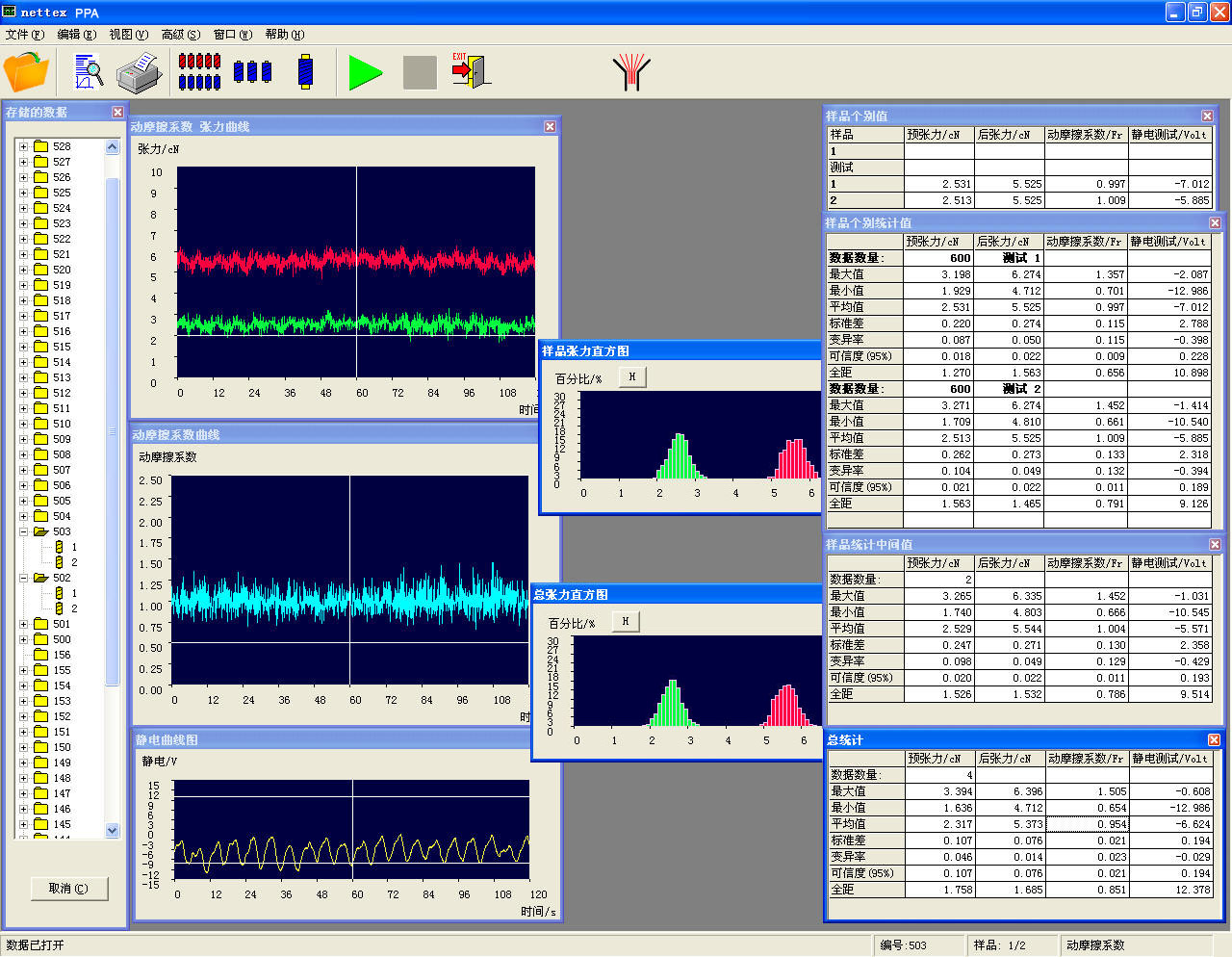

(1) |

Specific window

XP

English/Chinese

program provides

statistics,

analysis, save

and generate SPC

curve for

production

process

reference

purposes. |

|

|

(2) |

Specific window

XP

English/Chinese

program provides

statistics,

analysis, save

and generate SPC

curve for

production

process

reference

purposes. |

|

|

(3) |

Set typing in

advance or

display the

report only and

trans for PDF

file to email. |

|

|

(4) |

With database

software, the

measured value

can be

automatically

saved and save

into a database

format for data

query and

analysis. |

|

|

(5) |

May have access

control,

non-supervisory

personnel

permitted to

operate freely

without

passwords can

not use the

equipment |

|

|

(6) |

Continuous

testing and

storing

tests, up to

2400 hours. |

|

|

(7) |

Test curve

partial zoom

range of up to

0.1 ~ 7200

seconds |

|

|

(8) |

The same time,

digital display

and analog

output at the

same time. |

|

|

(9) |

Unique Inert , ½

Inert design can

optimization

curve and

analysis and

drawings easily. |

|

|

(10) |

Zoom drawing

partial: 1 -

3600 sec curve

away from its

own set grid

size can be

enlarged view

the subtle

changes of

curve. |