| |

|

|

|

Fiber

Intersection

Meter

FIM |

|

Back |

|

FIL

|

|

|

|

|

Fiber Intersection

sampling

FIP |

Fiber Intersection

Device

FID |

|

|

|

The above diagrams are

just for reference,

which may be changed

because of the user’s

software and the

experience of the

technicians |

|

|

|

|

|

|

|

Microscope |

|

|

● |

Total

Magnification: |

(1)The

magnification

through

collection

device is about

200X~2000X

|

|

|

|

(2)The

magnification

through 10X

eyepiece

40X/100X/200X/400X |

|

● |

Mechanism tube: |

160mm |

|

● |

Eyepiece tube: |

Binocular

coaxial bearing;

less than 0.1 up

and down, less

than 0.2 on

right and left;

light splitting

proportion:1:1; |

|

● |

Conversion

: |

Ball bearing

、internally

fixed conversion

with 4 orifice;

the 4-orifice

panel is the

same high,The

error less than

0.005,the

error of the

coaxial bearing

less than 0.03. |

|

● |

Focusing device

: |

Coarse

adjustment

switch coaxial

bearing and

focusing fixing

position device;

slipper

expansion V

model guide way;

Coarse stroke

25mm,fine

adjustment scale

0.002/grid;adjustment

device with

tension. |

|

● |

Worktable: |

V model guide

way,dual-layer

combined type

mechanism stage,the

area is 135×145

moveable range;

X direction

75mm,Y direction

50mm; on the

right hand

position,

vernire value

0.1 |

|

● |

Condenser: |

Vertically move

in gear wheel,

Abbe condenser,

aperture 1.25,

adjustable thin

sheet aperture

light bar, can

contain

φ32

color filter.. |

|

● |

Objective: |

Plan

panchromatic

objective4X、10X、

20X、

40X (inlaid

spring lens for

protection

system) |

|

● |

Color filter: |

Three kinds of

color filterφ32:blue,

green, and

yellow、frosted

glass. |

|

|

|

|

|

Collection

device: |

Three digital

imagery lens for

option(the

computer main

panel required

to support

USB2.0) |

|

● |

UVDC-300:(3

million color

element) |

|

● |

UVDC-200:(2

million color

element) |

|

● |

UVDC-130:(1.3

million color

element) |

|

|

|

|

|

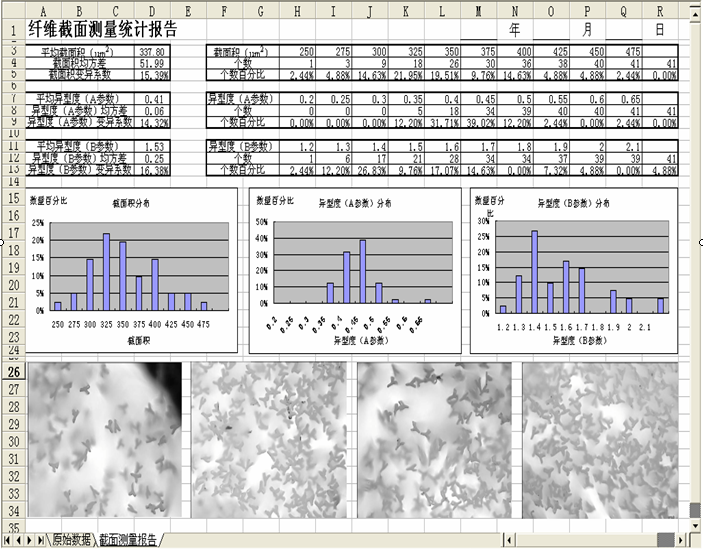

Software system(including

micrometer): |

|

inlaid report

setting process,

report content

and format can

be customized. |

|

● |

UV-A image

managing

software: photo

sample image、superimpose

scale、print

in fixed

magnification

and fixed

position |

|

● |

UV-P image

process

software: a.

photo sample

image、superimpose

scale、print

in fixed

magnification

and fixed

position;

b. test the

circumference,

diameter, and

acreage of fiber

intersection and

so on manually.

According to the

GB, test the

degree of

profile

and textile

group and so on

manually. |

|

|

CU-3 fiber(chemical

fiber )intersection

analysis system:

|

|

a. photo sample

image、superimpose

scale、print

in fixed

magnification

and fixed

position; |

|

b. test

the

circumference,

diameter, and

acreage of fiber

intersection and

so on manually; |

|

c. test the

degree of

profile

and textile

group and so on

manually |

|

d. Auto test

fiber

intersection

parameter,

degree of

profile, mean

square deviation

of degree of

profile、variation

coefficient、textile

group and so on. |

|

e. The test

certification

provided by

National

Institute of

Metrology (NIM),

P.R.China |

|

|

|

|

|

Option assistant

accessories: |

Stainless steel

wire, steel

wire, standard

trimmer, special

trimmer, black

fire, optical

microscope,

section

preparing

device, specific

holder, specific

light source,

specific glue

water, specific

grinding machine

, specific

reagent, optical

slides…..etc. |

|

|

|

|

|

|

|

|

|

● |

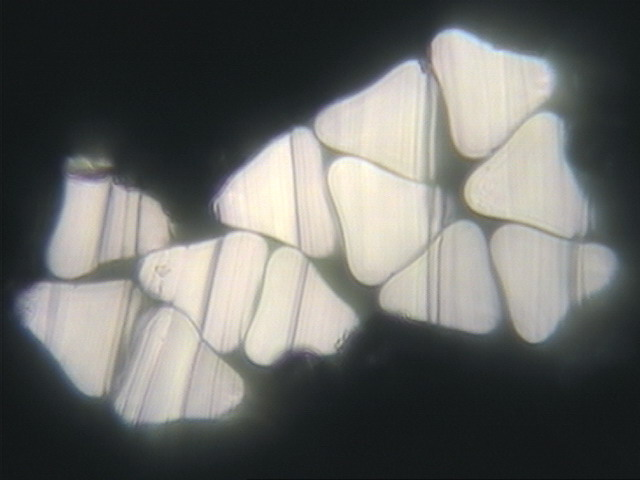

The test method

conforms to FZ/T

50002-1991 the

standard of

chemical fiber

degree of

profile test

and

AATCC-20A-1995

the regulation

of fiber fixed

quantity

analysis

standard. |

|

● |

Applicable to

kinds of usual

fiber and

variation fiber,

and to analyze

the character of

the fiber

intersection

mainly, to

provide service

to the

enterprises for

QC. |

|

● |

At present,

inspect the

state of

variation fiber

intersection

manually is very

hard,CU-3 can

auto inspect

the degree of

profile

directly, degree

of hollowness

and density… the

key parameter to

describe the

fiber

intersection. |

|

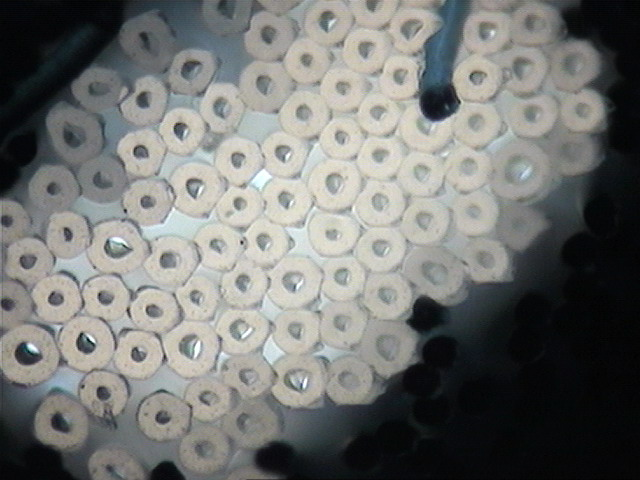

● |

Dozens of basic

geometry

parameter so

that the user

can inspect the

fiber

intersection in

many aspects,

and provide the

bran-new test

tool for the

research and

inspection. |

|

● |

Can classify the

mixed textile

fiber according

to different

intersection and

test the

separate

proportion auto(

the degree of

automation is

effected by the

level of making

sample, the

intersection is

required to be

clear and

sequent, and no

fall down fiber,

no nick and no

blot. |

|

● |

Image inspection

way directly,

provide high

effective auto

test procedures

and flexible

manual test tool

to finish the

test task of

large quantity

of data with

high accuracy,

to make the

previous

difficulty

intersection

inspection to

be the daily

inspecting item. |

|

● |

The report

format is

customized. |

|

● |

With fast

programming

tool, to make

different

disposal and

measuring way

depend on

different kind

of fiber. |

|

● |

Provide kinds of

fiber image

stock. |

|

● |

Test range 1~

1000μm |

|

● |

All-around

professional

configuration,

save manpower,

handle easily,

and resolve the

difficulty of

sampling and

low speed: |

|

|

1. |

with the

direction of

professional

technician, to

improve the

quality of

sampling

intersection

largely. |

|

|

2. |

get high

definition

observed with

microscope, to

improve the

accuracy of

manufacture for

the technician. |

|

|

3. |

Ample parts for

incising

different

samples, to

improve the work

efficiency and

speed. |

|

|

|